In the fast-paced world of food and beverage distribution, warehouse efficiency is paramount for businesses to stay competitive and meet customer demands. By streamlining operations and optimizing processes, companies can significantly enhance productivity, reduce costs, and improve customer satisfaction. In this blog, we will explore three essential steps to revolutionize food and beverage warehouse efficiency, paving the way for success in this dynamic industry.

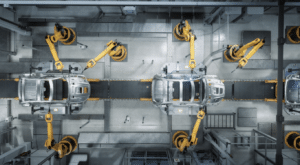

Step 1: Embrace Automation and Robotics

One of the most effective ways to enhance warehouse efficiency is by embracing automation and robotics. With technological advancements, sophisticated robotic systems are now available to streamline various aspects of warehouse operations. Implementing automation can significantly reduce labor costs and increase overall productivity.

Automated systems such as conveyor belts, robotic pickers, and autonomous forklifts can optimize the movement of goods within the warehouse. These systems can efficiently handle repetitive tasks, ensuring quicker and more accurate order fulfillment. Additionally, robotic systems can operate 24/7, maximizing operational efficiency and reducing processing time.

Furthermore, warehouse management systems (WMS) can be integrated with automation technology to provide real-time inventory tracking, seamless order processing, and improved data analysis. This integration enables businesses to make informed decisions, anticipate demand patterns, and optimize stock levels, thereby reducing the risk of overstocking or stockouts.

Step 2: Implement Data-Driven Strategies

To revolutionize warehouse efficiency, data-driven strategies play a crucial role. Collecting and analyzing data across various warehouse operations provides valuable insights to identify bottlenecks, streamline processes, and make informed decisions.

Utilizing Internet of Things (IoT) devices and sensors, warehouse managers can monitor and gather real-time data on inventory levels, temperature control, equipment performance, and more. This data can be analyzed to identify patterns, optimize storage layouts, and create predictive maintenance schedules to prevent equipment downtime.

Leveraging machine learning algorithms, businesses can predict demand patterns, optimizing stock levels and reducing wastage. Data-driven forecasting can help streamline the supply chain by identifying the most efficient routes for inbound and outbound logistics. By harnessing the power of data, businesses can make informed decisions, reduce costs, and enhance overall efficiency.

Step 3: Prioritize Workforce Training and Collaboration

Efficient warehouse operations are not solely reliant on technology but also on a well-trained and collaborative workforce. Investing in employee training programs and fostering a culture of continuous improvement can significantly impact efficiency and employee satisfaction.

Training programs should focus on equipping employees with the necessary skills to operate and maintain automated systems effectively. Additionally, cross-training employees across different areas of the warehouse can ensure flexibility and agility in responding to changing demands.

Encouraging collaboration among warehouse staff is equally vital. Regular team meetings and open communication channels foster a culture of sharing ideas, identifying process improvements, and solving problems collectively. Empowering employees to provide feedback and suggestions can lead to innovative solutions and a sense of ownership, ultimately driving warehouse efficiency.

Revolutionizing food and beverage warehouse efficiency requires a comprehensive approach that combines cutting-edge technology, data-driven strategies, and a well-trained workforce. Embracing automation and robotics optimizes operations, while data-driven strategies enhance decision-making and supply chain management. Prioritizing workforce training and collaboration ensures employee engagement and continuous improvement. By following these three essential steps, businesses can transform their warehouses into highly efficient and productive hubs, enabling them to stay ahead in the competitive food and beverage industry.

Contact RFW Construction Group, at info@rfwgroup.com to discuss your specific needs and explore how we can collaborate to expand your food and beverage capacities. Let RFW Construction Group be your trusted partner in building your ideal facility.

Photo Credit: Pexels.com – Tiger Lily