The automotive industry plays a crucial role in driving economic growth and technological advancement. Constructing automotive manufacturing and industrial facilities requires careful planning and attention to various key factors. In this blog post, we will discuss four essential things you need to know when embarking on such construction projects. These considerations will help ensure the successful implementation of your facility, optimize productivity, and maintain a competitive edge in the dynamic automotive sector.

1. Strategic Location:

Selecting the right location is paramount when constructing automotive manufacturing and industrial facilities. Several factors influence this decision, such as proximity to the market, availability of skilled labor, access to transportation networks, and infrastructure. Here are some key points to consider:

a. Market Proximity: Construct your facility close to your target market to reduce transportation costs and improve supply chain efficiency. Being closer to customers can also enable faster response times and enhance customer satisfaction.

b. Skilled Workforce: Assess the availability of a skilled labor pool in the chosen area. Access to a qualified workforce with automotive industry expertise will ensure smooth operations and promote productivity.

c. Transportation Infrastructure: Evaluate the transportation infrastructure, including road, rail, and port access. Efficient logistics and distribution networks are critical for receiving raw materials and delivering finished products.

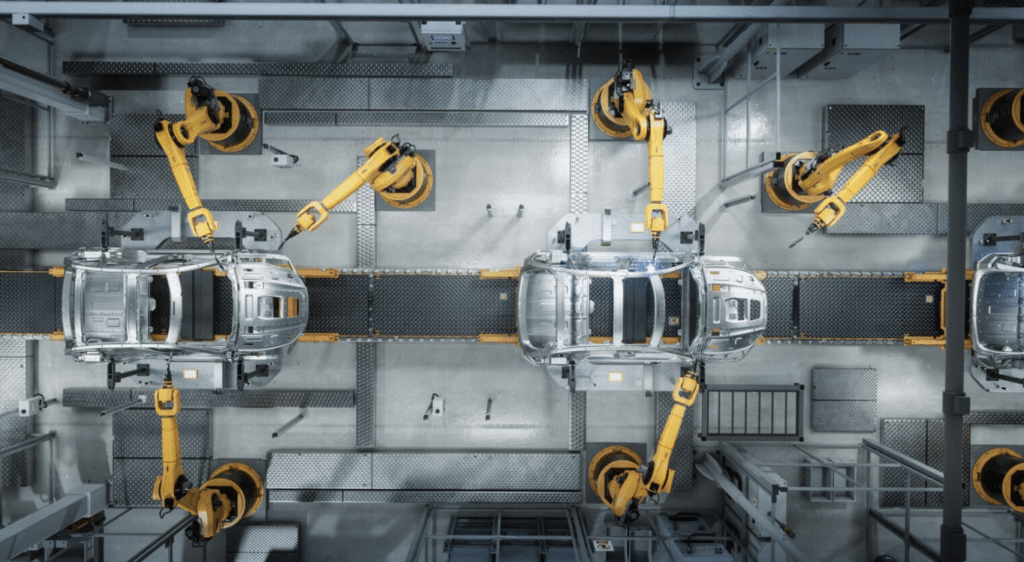

2. Efficient Facility Design:

Designing an automotive manufacturing and industrial facility that maximizes efficiency and productivity is essential. Consider the following aspects during the design phase:

a. Layout Optimization: Develop a facility layout that minimizes material movement, reduces production bottlenecks, and streamlines workflow. Utilize lean manufacturing principles to enhance efficiency and eliminate waste.

b. Flexibility and Scalability: Design the facility to accommodate future growth and changing production needs. Flexibility in layout and modular construction can allow for easy reconfiguration and expansion, ensuring adaptability to market demands.

c. Safety and Ergonomics: Prioritize worker safety by incorporating appropriate safety measures and ergonomic considerations into the facility design. Create a safe working environment that minimizes risks and promotes employee well-being.

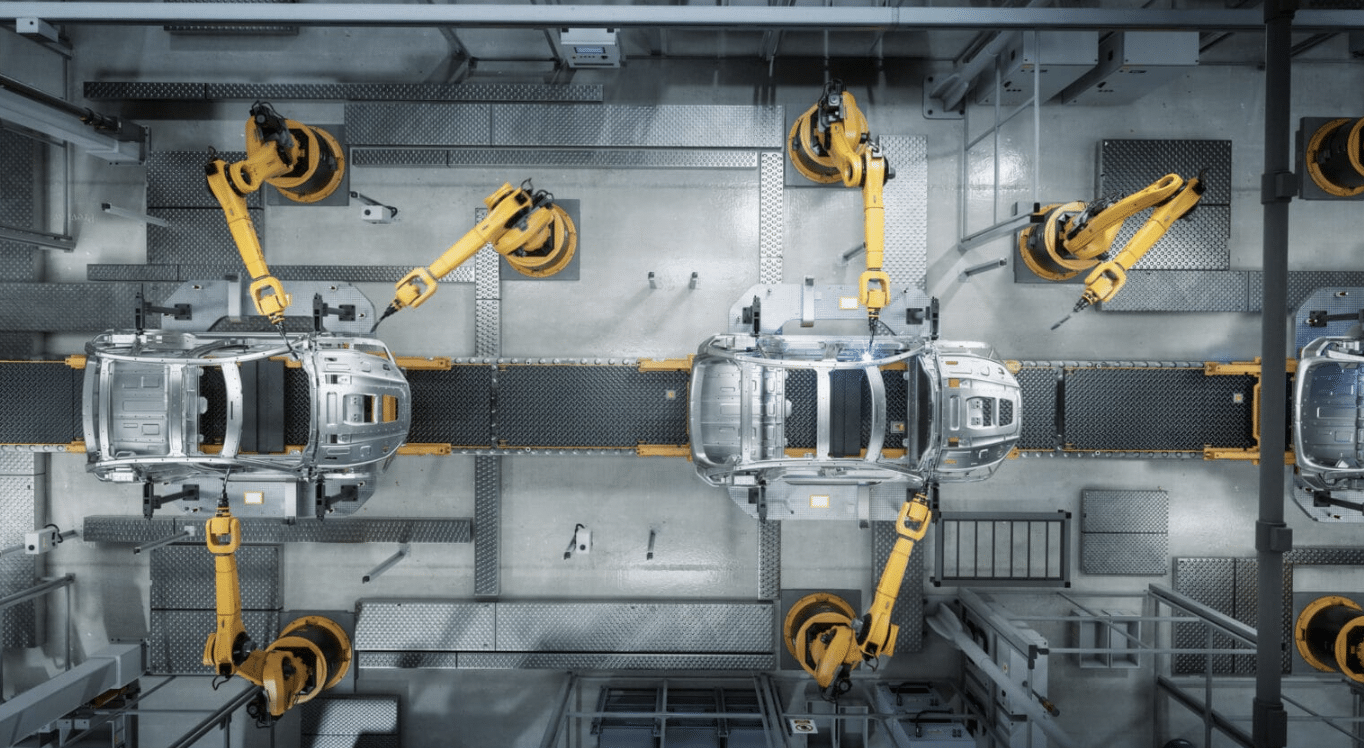

3. Advanced Technology Integration:

Leveraging advanced technology is crucial for remaining competitive in the automotive industry. Consider the following technological aspects during construction:

a. Automation and Robotics: Incorporate automation and robotics into your facility to enhance production efficiency, improve quality control, and reduce human error. Automated processes can increase output while maintaining high product standards.

b. Data Analytics and Connectivity: Implement data analytics tools and connectivity solutions to collect, analyze, and utilize real-time data for process optimization, predictive maintenance, and supply chain management. Harnessing the power of data can lead to informed decision-making and improved operational efficiency.

c. Internet of Things (IoT): Utilize IoT devices and sensors to monitor equipment performance, track inventory, and optimize energy consumption. IoT technology enables real-time monitoring, predictive maintenance, and enhanced production control.

4. Regulatory Compliance and Sustainability:

Complying with regulations and prioritizing sustainability are fundamental considerations for automotive manufacturing and industrial facilities. Keep the following points in mind:

a. Regulatory Requirements: Ensure compliance with local, regional, and national regulations concerning environmental standards, health and safety, labor laws, and building codes. Failure to comply can result in penalties, legal issues, and reputational damage.

b. Environmental Impact: Implement measures to minimize the environmental impact of your facility. Consider sustainable construction materials, water conservation systems, energy-efficient machinery, and waste reduction strategies.

c. Green Certifications: Seek green certifications, such as LEED (Leadership in Energy and Environmental Design) or BREEAM (Building Research Establishment Environmental Assessment Method), to demonstrate your commitment to sustainability. These certifications can enhance your reputation and attract eco-conscious partners and customers.

Constructing automotive manufacturing and industrial facilities requires an approach that considers location, efficient design, advanced technology, and regulatory compliance. By paying careful attention to these four essential factors, you can ensure the successful implementation of your facility, optimize productivity, and contribute to the growth and sustainability of the automotive industry. Embrace these considerations to stay competitive and meet the evolving demands of the automotive market.

RFW specializes in automotive construction, automotive plant expansions, automotive central utility plants and corporate headquarters. Contact us at info@rfwgroup.com to discuss your specific needs and explore how we can collaborate. Let RFW Construction Group be your trusted partner in building your ideal facility.

Photo credit: 4045 from Getty Images Pro