The design, bid, build process is now being plagued with uncertainty and frustration. This traditional construction process is facing issues and may no longer the most efficient or cost-effective way to complete construction projects. There are several reasons for this, which we will explore in this blog post.

Construction Materials

One of the biggest reasons why the design, bid, build process is facing challenges is because of the volatility of construction materials. Materials shortages have become highly unpredictable, and costs are constantly changing. This makes it difficult to determine which materials will be needed for a project, and how much they will cost. This issue was seen with the lumber price increase during the pandemic. As a result, projects often end up being more expensive than initially anticipated for developers.

In addition, trying to predict which construction materials will reach high-scarcity levels is extremely difficult. This can lead to construction delays, as developers try to obtain scarce materials. The uncertainty surrounding construction materials can make the design, bid, build process difficult. This also causes frustration for the customer as they must push back expectations on building finish dates.

Labor Costs

Another reason why the design, bid, build process may no longer be effective is because of the increasing labor costs. Construction workers are in high demand, and wages have been rising steadily over the past few years. This trend is expected to continue into the future, making it even more difficult to complete projects on time and on budget.

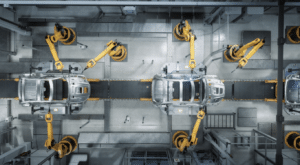

As labor costs continue to increase, developers are increasingly turning to prefabrication and modular construction methods. At times, these methods allow developers to complete projects faster and with less labor costs. As a result, prefabrication and modular construction are becoming popular among some developers who are looking for a more efficient way to build.

The design, bid, build process is currently being challenged as the most cost-effective way to complete construction projects. The volatility of construction materials and labor costs have made this process a bumpy ride for developers and customers alike. While the solution is yet to be determined, Andrew Volz, JLL Project and Development Services Americas research lead, has much to say on the topic. “Delays are pretty much universal at this point,” he says. “Developers will need to rework how they traditionally do projects as ‘design, bid, build’ no longer works.” He continues, “This challenge is forcing our PMs to be more creative, and they are asking questions such as ‘Can we find a separate supplier or go through a different process to get the needed materials; and is it possible to retrofit or use refurbished materials. It’s a whole new world of creativity to get all of this done and to get around what’s traditionally been our way of approaching supply chain and manufacturing. Just in time just isn’t working at this point.”

Source material: https://www.paintsquare.com/news/view/?25631