In an era of data-driven decision-making, the food and beverage industry has embraced predictive modeling as a powerful tool for forecasting, optimizing operations, and enhancing customer experiences. Predictive modeling utilizes historical data, statistical algorithms, and machine learning techniques to generate insights and make accurate predictions about future outcomes. By leveraging this technology, businesses can gain a competitive edge by anticipating market trends, optimizing supply chain management, improving product development, and personalizing marketing strategies. In this article, we will explore the transformative impact of predictive modeling on the food and beverage industry and delve into key applications and benefits for businesses in this dynamic sector.

- Forecasting Demand and Trends

Predictive modeling enables food and beverage companies to forecast consumer demand and identify emerging trends in the market. By analyzing historical sales data, customer preferences, social media trends, and external factors such as seasonality and economic indicators, businesses can make accurate predictions about future demand for specific products or categories. This allows companies to optimize production, minimize waste, and ensure sufficient stock levels to meet customer expectations. Additionally, predictive modeling helps identify emerging consumer trends, enabling businesses to proactively adjust their offerings and stay ahead of the competition. - Enhancing Supply Chain Efficiency

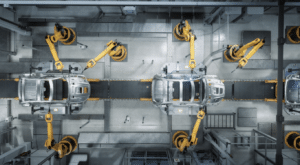

The food and beverage industry relies heavily on efficient supply chain management to ensure timely delivery of goods while minimizing costs. Predictive modeling can optimize various aspects of the supply chain, including inventory management, demand forecasting, logistics planning, and vendor selection. By analyzing historical data, market trends, and external factors such as weather patterns or transportation disruptions, businesses can optimize inventory levels, reduce stockouts, and streamline logistics operations. Predictive modeling also enables more accurate demand forecasting, facilitating better coordination with suppliers and reducing lead times. These improvements result in cost savings, improved operational efficiency, and enhanced customer satisfaction. - Optimizing Product Development and Innovation

Predictive modeling plays a crucial role in product development and innovation within the food and beverage industry. By analyzing consumer preferences, market trends, and competitor data, businesses can identify gaps in the market and develop new products that align with evolving consumer demands. Predictive modeling techniques, such as market segmentation and sentiment analysis, can help identify target demographics and refine product attributes to cater to specific customer needs. This data-driven approach minimizes the risk of product failure and increases the likelihood of success by aligning offerings with consumer preferences. - Personalizing Marketing and Customer Experiences

Predictive modeling enables businesses to personalize marketing campaigns and enhance customer experiences. By analyzing customer data, such as purchase history, browsing behavior, and demographic information, companies can create targeted marketing messages and promotions tailored to individual preferences. This level of personalization enhances customer engagement, increases conversion rates, and fosters customer loyalty. Additionally, predictive modeling can be used to optimize pricing strategies, recommend personalized product offerings, and provide targeted recommendations, further enhancing the overall customer experience. - Ensuring Food Safety and Quality Control

Food safety and quality control are paramount in the food and beverage industry. Predictive modeling can help businesses identify potential risks and ensure compliance with industry regulations. By analyzing data from various sources, including supply chain records, production processes, and environmental factors, predictive models can detect patterns or anomalies that may indicate potential food safety issues. This allows businesses to implement proactive measures to prevent contamination, reduce recalls, and maintain high-quality standards.

Predictive modeling has emerged as a game-changing technology in the food and beverage industry, empowering businesses to make data-driven decisions, anticipate market trends, and optimize operations. From forecasting demand and trends.

Let RFW Construction Group, an industry leader in food and beverage, and warehouse construction, transform your dreams into reality. With our wealth of expertise and unwavering commitment, we can assist your company in constructing a cutting-edge facility or revamping your existing one. Harnessing the potential of predictive modeling, we bring a new level of precision and innovation to every project. Whether you need to create a state-of-the-art storage space or incorporate the latest technological advancements, RFW Construction is prepared to be your partner of choice. Let us help you build a future that exceeds expectations! Contact RFW Construction Group at info@rfwgroup.com to discuss your specific needs and explore how we can collaborate. Let RFW Construction Group be your trusted partner in building your ideal facility.

Photo Credit: 4045 – Getty Images Pro; Chris VanLennep Photo – Getty Images; 3DFOX – Getty Images